RFID Label Solution

Achieve Item-level Tracking and Gain Visibility with SAG labels

RFID labels are more than just identification tools—they are key to streamlining operations, enhancing traceability, and optimizing efficiency across industries. Built with an aluminum antenna and an RFID chip, they offer seamless integration and long-term reliability in logistics, retail, pharmaceuticals, and industrial applications.

At SAG, we combine engineering expertise, material science, and one-roof manufacturing solutions to deliver RFID labels tailored to your needs—even in the most challenging environments.

Co-build with SAG

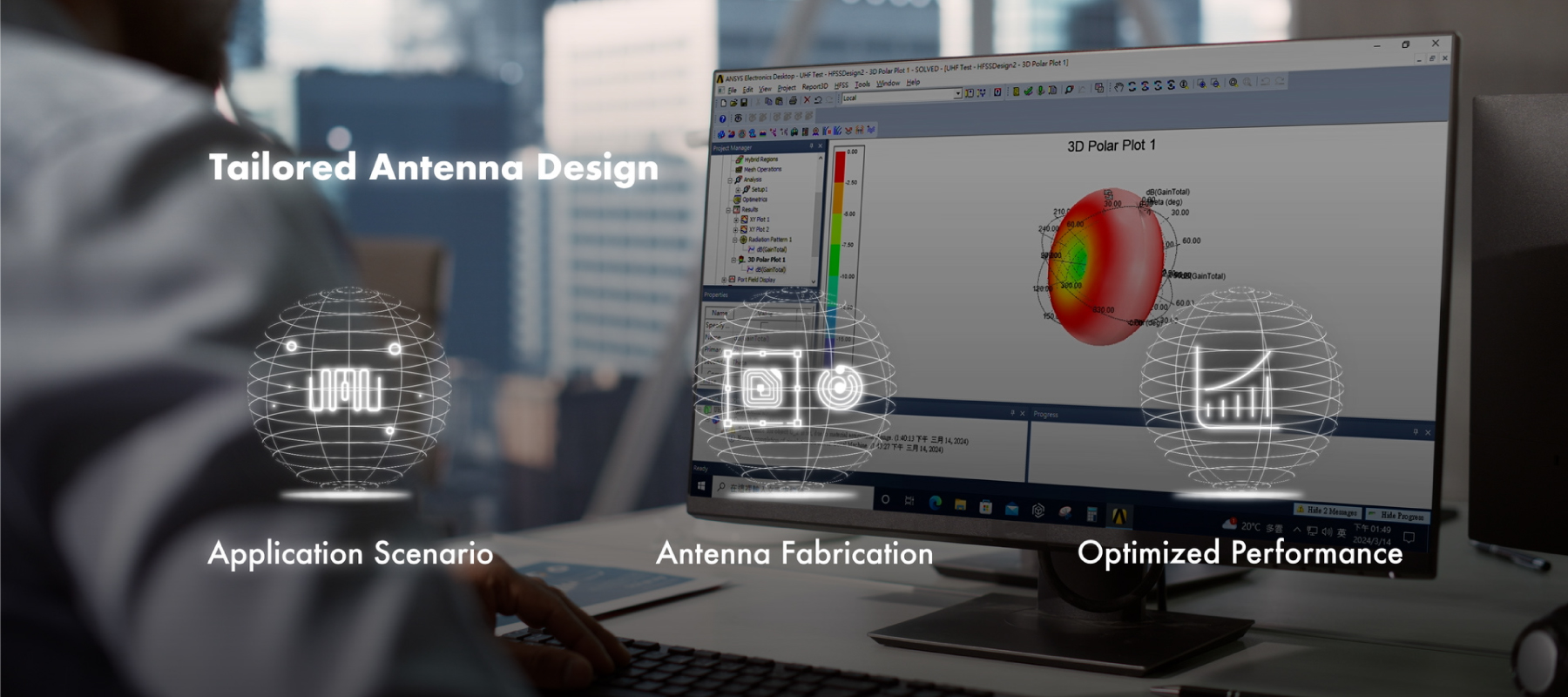

Antenna Design Capability

Material Science Engineering

In-house RFID Label Manufacturing

By addressing challenges like metal surfaces, liquids, and cross-interference, we enhance read accuracy and operational efficiency—even in demanding scenarios such as laboratories, where multiple interference factors may occur simultaneously.

Additionally, our labels can incorporate security cuts for tamper-evident functionality, helping users easily identify product integrity and usage status.

These materials ensure strong adhesion and durability in medical, industrial, and high-heat environments.

By selecting the right adhesive, we enable long-lasting RFID performance and reliable integration, even in harsh conditions.

Leveraging our advanced design house capabilities, we seamlessly integrate innovative engineering with precision manufacturing to deliver RFID labels that meet the highest industry standards.

With customizable perfect-roll selection, reliability testing (thermal shock, mechanical stress like die shear and bending, electrical resistance), and automated inspection, we maintain high quality assurance.

Supported by self-developed equipment, our process guarantees RFID labels with durability, accuracy, and dependable performance across applications.

The PC core option is ideal for laboratories, medical settings, and other dust-sensitive applications—providing a cleaner, more controlled alternative to traditional core materials.

SAG Label Solutions

On Metal RFID Labels

Built for customization— Contact Us to find the ideal RFID label for your unique application.

They ensure reliable tracking of assets such as tools, machinery, and containers. SAG’s on-metal solutions deliver exceptional durability and accuracy, even in harsh, interference-heavy environments.

Built for customization— Contact Us to find the ideal RFID label for your unique application.

18 x 35 HF Metal Label

Anti-Liquid RFID Labels

Built for customization— Contact Us to find the ideal RFID label for your unique application.

Commonly used in healthcare, food, beverage, and laboratory environments, these labels enable accurate tracking of items like medications, bottled goods, and chemical containers across complex supply chains.

Built for customization— Contact Us to find the ideal RFID label for your unique application.

NFC Labels

Whether used to authenticate industrial components or connect users with digital content, they enhance traceability and storytelling across phygital experiences, offering a simple tap-to-connect solution for modern product interaction.

Specialty Labels

Ideal for complex environments like medical devices, RTIs, or industrial systems, these labels deliver added value through precise tracking, condition monitoring, and enriched data capture beyond standard identification tasks.

Temp Tracker

Have More Questions?

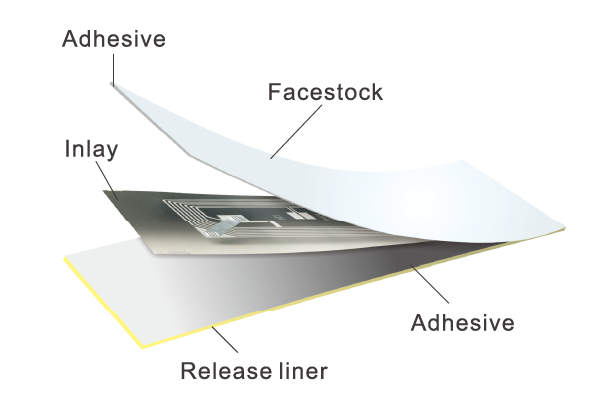

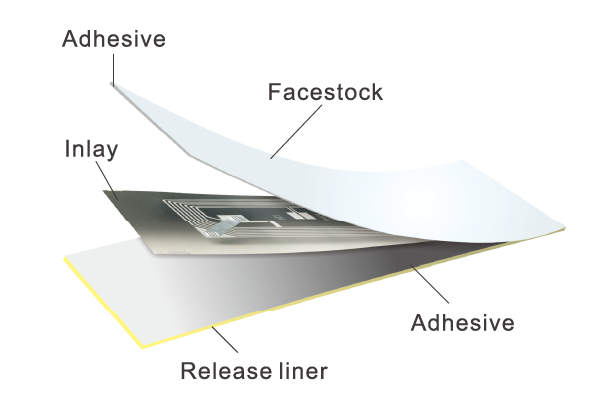

RFID smart labels feature a simple yet highly effective form factor, comprised of an aluminum antenna and an RFID chip.

SAG delivers comprehensive, end-to-end RFID label solutions, tailored to your needs and designed to overcome any RFID tagging challenges. Discover our full range of RFID labels to optimize your operations.

FRAM Tag uniquely features its capability to survive the radiation of gamma ray during the sterilization process for surgical tools used in a hospital. Ferroelectric RAM (FRAM) is a memory technology that combines the...

FRAM Tag uniquely features its capability to survive the radiation of gamma ray during the sterilization process for surgical tools used in a hospital. Ferroelectric RAM (FRAM) is a memory technology that combines the best of RAM and ROM.

FRAM Tag uniquely features its capability to survive the radiation of gamma ray during the sterilization process for surgical tools used in a hospital. Ferroelectric RAM (FRAM) is a memory technology that combines the best of RAM and ROM. It is ideal for applications that require high-performance, non-volatile and large memory. FRAM offers several major advantages over EEPROM, including its read/write speed, endurance, low power consumption, higher security, and tolerance for radiation. Looking at all these features, SAG has hard tag product with MB89R118/119/112 powered by Fujitsu to target demands from industrial to health care sectors.

SAG works with STMicroelectronics on labels and tags with the latest ST25TV and ST25TN chip series. See a portfolio of products we create for your customer engagement, medical, consumer electronics and more advanced NFC applications

FRAM Tag uniquely features its capability to survive the radiation of gamma ray during the sterilization process for surgical tools used in a hospital. Ferroelectric RAM (FRAM) is a memory technology that combines the...

FRAM Tag uniquely features its capability to survive the radiation of gamma ray during the sterilization process for surgical tools used in a hospital. Ferroelectric RAM (FRAM) is a memory technology that combines the best of RAM and ROM.

FRAM Tag uniquely features its capability to survive the radiation of gamma ray during the sterilization process for surgical tools used in a hospital. Ferroelectric RAM (FRAM) is a memory technology that combines the best of RAM and ROM. It is ideal for applications that require high-performance, non-volatile and large memory. FRAM offers several major advantages over EEPROM, including its read/write speed, endurance, low power consumption, higher security, and tolerance for radiation. Looking at all these features, SAG has hard tag product with MB89R118/119/112 powered by Fujitsu to target demands from industrial to health care sectors.

Speaking of IoT, NFC technology plays an important role to connect things. SAG has been in partnership with STMicroelectronics to provide tags and labels for a wide variety of applications to truly realize its vision of Life Augmented. Strong at NFC technology, STMicroelectronics provides NFC forum certified Type 4 and Type 5 ST25T series for NFC tags and ST25D series for dynamic tag with unique features to go more advanced use cases such as parameter setting and convenient pairing. With different form factors in our product portfolio, we will ready your NFC applications.

| Die Cut Size / Antenna Size(mm) | IC |

| Φ15 /Φ13 | NTAG213 |

| Φ25 / Φ23 | Mifare Classic EV1 1K NTAG215 / 216 ICode SLIX 2 ST25TV02K ST25TV512C |

| Φ27 / Φ23 | Mifare Ultralight EV1 Mifare Classic EV1 1K |

| Φ27 / Φ24.2 | Tag-it HF-I Plus / I Pro |

| Φ28 / Φ25 | ST25TV512C |

| Φ29 / Φ25 | EM4332 Mifare Ultralight EV1 / C Mifare DESFire EV1 256B NTAG213 / 215 / 216 ICode SLIX / SLIX 2 NTAG424DNA Felica RC-S966 ST25TA02KB ST25TV512 / 02K ST25TN01K |

| Φ38 / Φ34 | NTAG213 ICode SLIX |

| 10 x 10 / 8.5 x 8.5 | ICode SLIX |

| 12.5 x 12.5 / 10.5 x 10.5 | ICode SLIX |

| 14 x 14 / 12 x 12 | NTAG213 |

| 14.5 x 14.5 / 10.5 x 10.5 | ICode SLIX ST25TV02K |

| 16 x 16 / 12 x 12 | NTAG213 / 215 / 216 ST25TA02KB |

| 18 x 18 /14.5 x 14.5 | ST25TV02K / 02KC |

| 19 x 19 / 15 x 15 | NTAG213 / 215 / 216 ICode SLIX |

| 18 x 35 / 14 x 31 | NTAG213 ICode SLIX / SLIX 2 ICode ILT-M ST25TV512 |

| 26.5 x 42 / 22.5 x 38 | Mifare Ultralight EV1 / C Mifare Classic EV1 1K NTAG213 / 215 / 216 NTAG213TT ICode SLIX / SLIX S Felica RC-S966 ST25TV02KC Tag-it HF-I Plus / I Pro |

| 54 x 86 / 45 x 76 | Mifare Ultralight EV1 / C Mifare Classic EV1 1K NTAG213 Tag-it HF-I Plus / I Pro |

| 50.8 x 50.8 / 45 x 45 | ST25TV02K / 02KC Tag-it HF-I Plus / I Pro |

| 30 x 45 / Embedded Antenna by IC type | ICode SLIX Mifare Classic EV1 1K Mifare DESFire EV1 4K / 8K Mifare Ultralight EV1 / C NTAG213 Legic MIM256 Legic ATC256 / ATC1024 |

| 52 x 52 / Embedded Antenna by IC type | ICode SLIX Mifare Classic EV1 1K Mifare DESFire EV1 4K / 8K Mifare Ultralight EV1 NTAG213 Legic MIM256 |

| 42 x 26.5 / 37 x 21 | ST25TV02KC-T |

| Antenna | Die Cut Size / Antenna Size(mm) | IC |

| 22 x 45 / 18 x 30 | Impinj R6 |

| 25 x 43 / 20 x 39 | Impinj R6 |

| Ф15 / Ф12 | Impinj Monza 4 |

| 12 x 26 / 8 x 22 | Impinj Monza 4 |

| 19.05 x 30 / 16 x 26 | Impinj Monza 4QT |

| 19.05 x 44.45 / 15 x 40 | NXP Ucode 8 |

| 33 x 53 / 30 x 50 | NXP Ucode 8 |

| 48 x 48 / 44 x 44 | Impinj Monza 4 |

| 6 x 94 / 3 x 90 | Impinj Monza 4 |

| 12 x 98 / 8 x 95 | Impinj R6-P |

| 17 x 72 / 15 x 70 | Impinj R6 |

| 23.2 x 96.5 / 19 x 90 | Impinj R6 |

- Metal and liquid surfaces: These materials could reflect or absorb radio waves, reducing the performance of RFID labels.

- Size and shape of the surface: For small or irregular surfaces, choose miniaturized or custom-shaped RFID labels with specialized adhesives for better performance.

- Weather Conditions: RFID labels should withstand rain, humidity, UV exposure, or other weather elements when used outdoors.

- Temperature Conditions: When being in the process with extreme temperatures, specialized RFID labels are needed. RFID labels are suitable for managing trays in labs or for use in long, narrow surfaces like those found in cold storage environments.

- Harsh Physical Conditions: In environments with intense vibration, impacts, or rough handling, which are common in handling, transportation, and warehousing environments. Impact-resistant labels are essential to ensure reliable performance under harsh conditions.

You can explore a wild range of metal and non-metal labels with our product selector or contact us for expert guidance tailored to your specific needs. For more information on RFID technology, check out our guide: Mastering RFID Tags: A Complete Guide with Selection Tips.

- Tel : +886-4-2492-5298

- Fax : +886-4-2492-7388

- Email:info@sag.com.tw

- Tel : +81-3-5988-7809

- Fax : +81-3-5983-0807

- Email:info@sag.com.tw