Choose Year

Mastering RFID Tags: A Complete Guide with Selection Tips

RFID (Radio Frequency Identification) is a technology that uses radio waves to wirelessly identify and track objects. RFID tags have become a familiar part of everyday life, commonly found in retail stores for self-checkout, allowing multiple items to be scanned in seconds, and in automatic vehicle identification (AVI) systems on highways for seamless toll collection. Beyond these everyday applications, RFID is also crucial in supply chain management, inventory control, and tracking systems, where it helps streamline operations, reduce errors, and boost overall efficiency.

RFID has proven its value across various industries over the past two decades, shaping the digital landscape and enabling a more connected world in everyday life. Early uses focused on inventory management in retailer and asset tracking in Work-in-Process., but with significant advancements, particularly in extended read range, speed, and enhanced security, RFID has become indispensable in vertical segments like healthcare (e.g., patient tracking and medication management), manufacturing (e.g., automation and quality control), logistics (e.g., real-time supply chain tracking), and the Internet of Things (IoT). Furthermore, RFID is now evolving into a key enabler of Digital Product Passports (DPP) , facilitating product transparency and sustainability, and expanding its influence in the digital age.

- Low Frequency (LF):Operating at 125-134 kHz, LF RFID systems offer short-range communication, typically under 10 cm. These are ideal for environments with metal or water interference, such as animal tracking, where livestock tags are widely used for identification and management. LF RFID tags are regulated under ISO 11784 and ISO 11785, which define the structure of the data on the tag and the communication protocol between the tag and reader, ensuring consistent and reliable performance in these applications.

- High Frequency (HF) / Near Field Communication(NFC): Both HF and NFC operate at 13.56 MHz, providing secure and fast data transfer. HF RFID is commonly used for access control, contactless payments, and public transport systems, using standards ISO 14443 for short read ranges up to 10 cm and ISO 15693 for longer read ranges up to 1 meter. NFC, a subset of HF, allows close-range, peer-to-peer communication (up to 10 cm), enabling mobile payments, smart device interactions, and tap-to-pay systems with protocols ISO 18092.

- Ultra-High Frequency (UHF) / RAIN RFID: Operating between 860-960 MHz, UHF RFID—commonly known as RAIN RFID—enables long-range communication, making it ideal for inventory management, logistics, and supply chain automation. With read distances ranging from several meters up to 10 meters, RAIN RFID systems, such as those using the EPCglobal Gen2 (ISO 18000-63) standard, allows fast, bulk scanning of items without requiring direct line-of-sight. This technology is widely adopted in retail and industrial sectors, offering powerful capabilities for tracking and managing assets across large areas.

| Frequency Band | Frequency | Read Range | Key Protocols |

|---|---|---|---|

| Low Frequency (LF) | 125-134 kHz | under 10 cm | ISO 11784 ,ISO 11785 |

| High Frequency (HF) | 13.56 MHz | 10 cm - 1 meter | ISO 14443, ISO 15693 |

| Near Field Communication (NFC) | 13.56 MHz | up to 10 cm | ISO 18092 |

| Ultra-High Frequency (UHF) | 860-960 MHz | up to 10 meters | EPCglobal Gen2 (ISO 18000-63) |

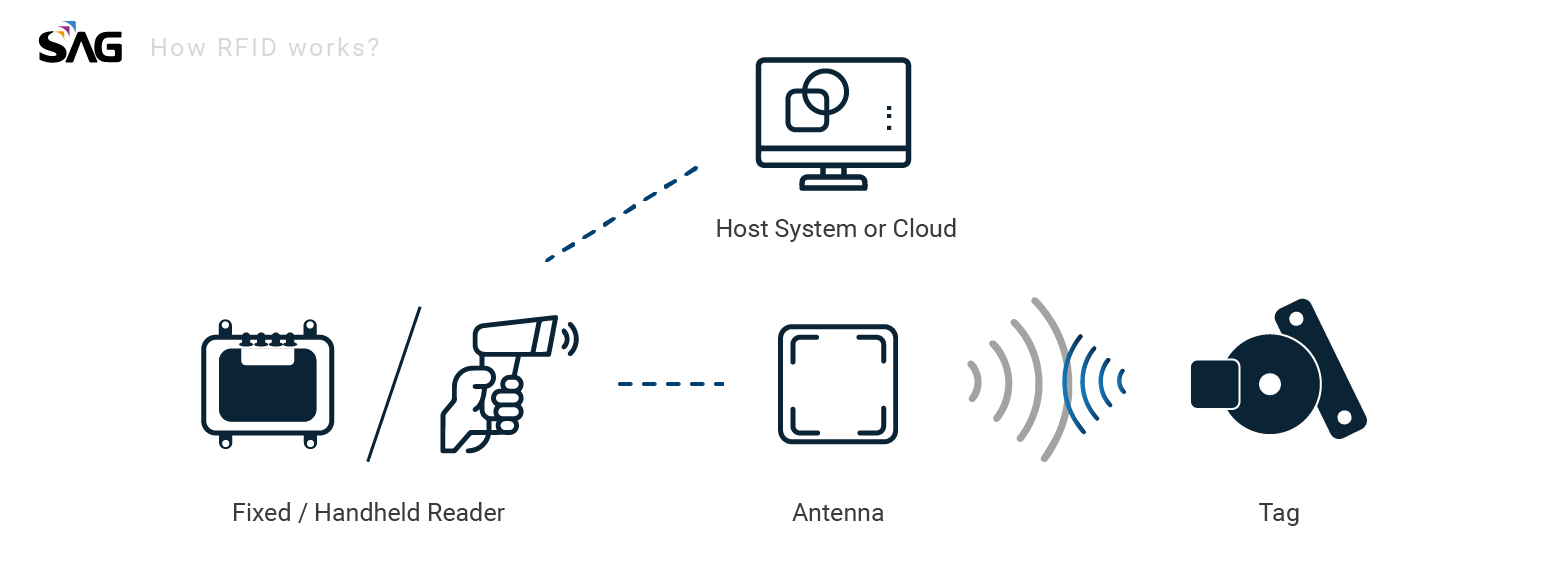

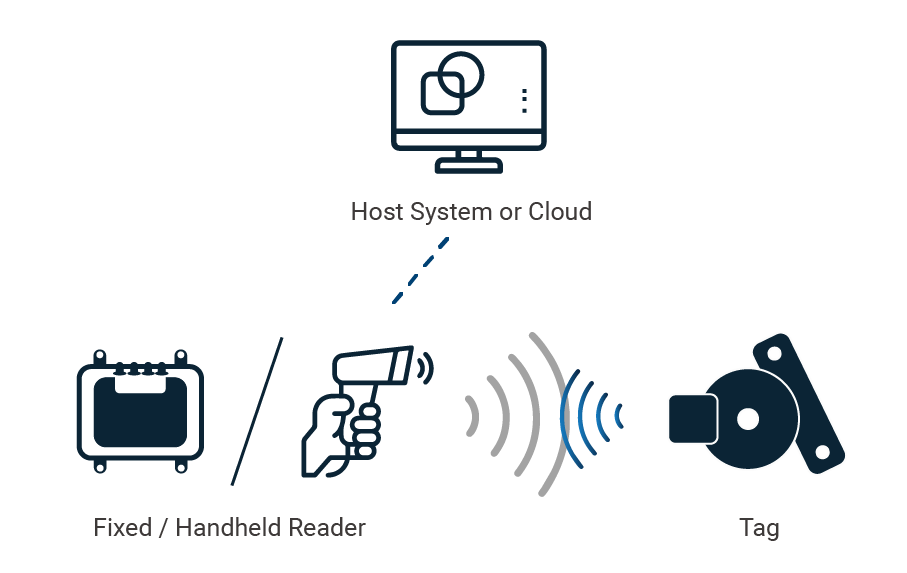

- Signal Transmission: RFID Reader: Sends out radio waves to locate and activate nearby RFID tags. In passive systems, the reader also provides power to the tags, while active tags have their own power source. The reader's signal enables communication by triggering the tag's response.

- Signal Reception: RFID Tag: The RFID tag, composed of an antenna and microchip, receives the signal from the reader. In passive tags, the received signal powers the tag. In active tags, the battery assists with signal processing and communication. Antenna Activation:The antenna on the tag captures the signal, activating the tag's microchip and preparing it for data transmission.

- Data Response: Data Processing: Once activated, the tag processes the signal and retrieves stored data, such as a unique identifier (UID), item information, or other encoded details. Data Transmission: The tag transmits the processed data back to the reader. UHF tags use backscatter technology, reflecting the reader’s signal, while LF and HF tags rely on inductive (magnetic) coupling for data transmission.

- Data Capture: Reader Reception: The RFID reader captures the transmitted data from the tag, converting it into a digital format for further processing. Data Integration: The collected data is sent to a central database or information system, where it can be used for tasks like inventory management, tracking, authentication, or further processing.

- Active RFID Tags: These tags contain a built-in power source, usually a battery, which allows them to transmit signals over greater distances. Active tags are commonly used in applications like Real-Time Locating Systems (RTLS), asset tracking, and environmental monitoring. While they offer extended range and functionality, they tend to be more expensive and require periodic battery replacements.

- Passive RFID Tags: Passive tags, on the other hand, have no internal power source. Instead, they rely on the energy from the RFID reader’s signal to activate and transmit data. This makes passive RFID tags more cost-effective and easier to maintain, which is why they are widely used in industries for large-scale applications like inventory management and supply chain tracking.

- Inlay and Label: Commonly used in packaging and logistics for tracking goods in retailers, inventory management, and pharmaceutical packaging. These tags are typically embedded in product labels and are ideal for scalable, high-volume applications, such as item-level tracking in consumable goods.

- Hard Tag: Built for asset management and industrial use, where durability is essential. Encased in rugged materials, hard tags withstand harsh environments and are commonly used for tracking heavy equipment, tools, and machinery in industrial applications where Work in Process (WIP) tracking is involved.

- Cards & Keyfob: Frequently used in access control, identification, and cashless payment systems. These form factors are popular in settings like office buildings, hotels, multi-family building and public transportation, offering secure and convenient identification.

- Sensor Tag: Designed for IoT applications where they monitor environmental conditions such as temperature, humidity, and pressure, they are ideal for cold chain management, environmental monitoring, and industrial process control. providing real-time data to help ensure a higher level of product quality and safety, and operational efficiency.

Enhanced Efficiency

Improved Visibility

Enhanced Accuracy

Increased Security

Reduced Cost

Enhanced Customer Engagement

- Enhanced Efficiency: RFID technology promote efficiency by automating data collection, reducing the need for manual labor, and speeding up processes. Since RFID can scan multiple items at once without requiring direct line-of-sight, it significantly shortens processing times.Example: In highly automated factories, companies use RFID to tag tools and machinery, enabling quick asset location and automated maintenance scheduling. This ensures efficient equipment usage, prevents downtime, and eliminates the need for manual equipment checks, resulting in smoother operations and lower labor costs.

- Improved Visibility: RFID provides real-time insights into the location and status of inventory, allowing businesses to track products throughout the supply chain with high precision. This enhanced visibility helps companies make informed decisions, prevent stockouts, and optimize inventory levels.Example: RFID technology has become a well-established solution in the apparel industry for tracking textiles from the warehouse to the sales floor. With RFID tagging on every item, retailers can quickly locate products, ensure accurate stock levels, and efficiently replenish shelves, minimizing out-of-stock situations and enhancing consumer shopping experience and engagement.

- Enhanced Accuracy RFID technology enhances accuracy by automating identification, reducing errors from manual processes like barcode misreads or missed scans. This results in more reliable and accurate inventory data. When integrated with IoT systems, RFID can instantly log and monitor product details, including counterfeit detection and expiration dates, ensuring real-time tracking and up-to-date information.Example: In hospitals, RFID-equipped smart cabinets revolutionize medication management by automatically tracking drugs as they are added or removed. This ensures real-time visibility into inventory, reduces manual errors, and automates the monitoring of expiration dates and controlled substances. By providing precise, automated data, smart cabinets enhance patient safety, prevent medication errors and counterfeiting, and ensure that critical drugs are always available when needed. They drive healthcare digitization, streamline compliance with regulatory standards, and allow healthcare providers to focus on delivering a better level of patient care.

- Increased Security RFID enhances security by enabling item-level authentication and preventing counterfeit goods from entering supply chains. Tags can be encrypted to prevent unauthorized access, and authentication features ensure that only genuine products pass through checkpoints.Example: A pharmaceutical company embeds RFID tag in product packaging to securely track medications from the manufacturing facility to the pharmacy. By integrating blockchain technology, each tagged product’s movement is logged in an immutable digital ledger, ensuring both real-time traceability and protection against counterfeiting. The combination of RFID and blockchain prevents unauthorized tampering and ensures that only authentic products reach consumers, while maintaining an unalterable record of every transaction.

- Reduced Cost RFID reduces labor costs by automating routine tasks such as inventory management and asset tracking. It also decreases waste by providing more accurate demand planning and reducing overproduction or excess inventory. Example: In logistics, companies use RFID to automate sorting and tracking of packages in fulfillment centers. This reduces the need for manual handling and minimizes sorting errors, mitigate hidden cost associated with errors downtime and inefficiencies, further lowering overall operational costs.

- Enhanced Customer Engagement RFID technology bolsters customer engagement by providing personalized, real-time interactions and improving the overall shopping experience. It enables businesses to offer tailored experiences based on specific preferences and behaviors.Example: A renowned knitwear company employs NFC technology to create a unique and interactive customer experience. Each garment is tagged with an NFC tag that allows customers to access detailed information about their knitwear by simply tapping their NFC-enabled smartphone. This feature provides insights into the product’s journey, including the origin of the wool and real-time updates about the sheep that provided. Such direct interaction deepens the customer’s connection with the brand, making the shopping experience more engaging, informative, and memorable. By seamlessly integrating online and offline experiences, Sheep Inc. fosters branding loyalty and enhances customer satisfaction. Read More

- Improved Sustainability By providing real-time visibility into inventory and supply chains, RFID enables companies to reduce waste, optimize resource usage, and cut down on energy consumption. RFID is also an ideal tool for implementing Digital Product Passports (DPP), as it allows products to carry detailed, traceable information throughout their lifecycle. By linking RFID tags to a digital database, companies can store critical data about a product’s origin, materials, and sustainability attributes, ensuring transparency and compliance with environmental standards. Example: A global textile retailer attaches RFID tags to nearly all of its apparels from the moment of manufacturing, enabling real-time tracking and helping to avoid overproduction and waste. In stores, RFID allows the retailer to closely monitor inventory levels and quickly identify best-selling items, leading to more efficient restocking and production planning. Beyond the point of sale, the retailers leverage RFID to support the recycling, reselling, and reuse of products by tracking each item’s lifecycle, ensuring sustainable management even after purchase. By linking RFID tags to a digital database, the company ensures that each product’s materials, origin, and sustainability attributes are traceable, aligning with their environmental goals, transparency standards, and Digital Product Passports (DPP).

Healthcare and Pharmaceutical:

Automation and Manufacturing

Logistics

Automotive

Retail

Branding

Acesses Control

Others

- Healthcare and Pharmaceutical: RFID tags are widely used in healthcare to enhance patient safety, streamline asset tracking, and safeguard medication management. They allow hospitals to monitor equipment, track patient movements, and ensure the correct administration of medication. In the pharmaceutical industry, RFID helps ensure the authenticity of drugs, prevents counterfeiting, and monitors the storage conditions of temperature-sensitive medications.

- Automation and Manufacturing: In manufacturing, RFID is exercised to automate processes, lift efficiency, and reduce errors. It enables real-time tracking of materials and products on the production line, enhances inventory control, and facilitates machine-to-machine communication. RFID tags also provide crucial data streams that feed into digital twins—virtual replicas of physical objects—supporting Digital Data Chain (DDC). This integration allows manufacturers to optimize production flow, predict maintenance needs, and forecast potential errors before they disrupt operations. By tagging both raw materials and finished goods, manufacturers can ensure accurate order fulfillment and enhance overall operational reliability. The combination of RFID and digital twins helps in precise tooling maintenance, predictive analytics, and improved automation, driving significant gains in manufacturing efficiency and accuracy.

- Logistics: RFID technology is integral to modern logistics, enhancing visibility across the supply chain with real-time shipment tracking, inventory management, and product authentication. It boosts warehouse efficiency by automating goods tracking and reducing labor costs. When combined with Returnable Transport Item (RTI) tracking, RFID optimizes the management of reusable assets, cuts transportation costs, and minimizes environmental impact. This synergy drives savings and supports a more sustainable, efficient supply chain.

- Automotive: RFID technology has become a cornerstone in modern automotive manufacturing, ensuring efficient tracking and management of vehicle components throughout the production process. RFID tags, designed to endure harsh conditions such as extreme heat and vibrations, are applied to car bodies and parts, enabling real-time monitoring as they move through various stages of assembly. This ensures that the right components are used at the right time, reducing errors and increasing efficiency. Moreover, RFID systems provide manufacturers with detailed insights into production flow, making it easier to maintain quality control and manage recalls. By integrating RFID into the automotive supply chain, manufacturers achieve greater accuracy, streamlined operations, and enhanced overall productivity.

- Retail: RFID tags are transforming the retail sector by improving inventory accuracy, reducing product shrinkage, and enhancing the shopping experience. Retailers can track individual items throughout the supply chain, ensuring products are always available on shelves. RFID also supports omnichannel strategies, allowing for faster restocking and seamless integration between online and physical stores.

- Branding: For brands, RFID technology offers a powerful tool for product authentication and protection against counterfeiting. By embedding RFID tags in luxury goods, apparel, or electronics, companies can verify the authenticity of their products at every stage of the supply chain, helping to maintain brand integrity and consumer trust.

- Access Control: RFID is commonly used in secure access control systems for buildings, events, and transportation. By using RFID cards or badges, organizations can grant or restrict access to specific areas, monitor entry and exit times, and enhance overall security.

- Others: Beyond the industries mentioned, RFID has found applications in various other fields, such as agriculture for livestock tracking, libraries for book management, and event management for tracking attendees. Its ability to automate processes, reduce human error, and provide real-time data makes RFID a versatile solution across numerous sectors.

Tagging Surface

Environment for Tagged Items

Usage Scenario

Security Requirements

- Surface Material: Different materials affect how RFID tags perform. For example:

- Metal and liquid surfaces can reflect or absorb radio waves, reducing the performance of RFID tags. Special tags designed for metal surfaces (on-metal tags) or liquid-filled containers should be used.

- Plastic, cardboard, fabric, and wood are less problematic, but still, testing the tag’s readability on these materials is essential.

- Size and Shape of the Surface: If the surface area is small, you may need to choose miniaturized RFID tags or RFID labels that fit without interfering with the aesthetics or functionality of the tagged product.

- Weather Conditions: If RFID tags are used in outdoor environments, they must be able to withstand rain, humidity, UV exposure, or other weather elements. Robust and waterproof tags are necessary to ensure long-term performance in such environments, protecting them from potential degradation.

- Temperature Conditions (including Work-In-Process): If the tagged items are in the process with extreme temperatures, such as cold storage or high-heat industrial settings (e.g., ovens), specialized RFID tags are needed. Tags exposed during different stages of work-in-process (WIP) may require durable materials to handle these conditions, ensuring reliable performance throughout the manufacturing or storage process.

- Chemical Exposure:In industries where RFID tags might encounter corrosive chemicals (e.g., pharmaceuticals or chemical production), choose chemical-resistant tags. These tags are typically encased in protective materials like silicone or hard plastic to prevent damage and maintain functionality.

- Harsh Physical Conditions:Environments with high levels of vibration, impacts, or rough handling (such as logistics or heavy manufacturing) require ruggedized RFID tags. These tags are built to be tough, ensuring that they continue to function even when subjected to physical stress during transportation or usage.

- Sterilization Processes:In hospitals or laboratories, some of medical devices must withstand rigorous sterilization methods such as Ethylene Oxide (EtO), autoclaving, and gamma radiation. These tags are specifically designed to endure these harsh processes without compromising data integrity or performance. With resistance to extreme heat, pressure, and radiation, these tags ensure reliable traceability for medical devices throughout repeated sterilization cycles, making them ideal for use in hospitals and other healthcare settings.

- Read Range:

- Long-range Tracking Items: UHF tags are the ideal for tracking items over larger distances, such as in warehouse inventory management or logistics, where objects need to be tracked from several meters away.

- Short-range Checking Items: HF or NFC tags are the best for close-range applications like payment systems or product authentication , where proximity is key for security and accuracy.

- Type of Reader:

In addition to selecting the appropriate technology, the type of reader is another important factor to consider.

- Handheld readers are often used for item-level scanning in retail or inventory systems, allowing operators to target specific items with greater accuracy.

- Fixed readers can be installed at strategic points, such as doorways or conveyor belts, to efficiently read multiple items as they pass through, using anti-collision technology to ensure accurate tracking of items per second.

- Antennas and reader configurations can be fine-tuned to focus on a specific reading zone, preventing multiple tags from being read at once. This is especially critical when items are stored close together but need to be tracked individually.

- Data Encryption: RFID tags can hold sensitive information, so data encryption on the tag and during communication with the reader may be necessary to prevent unauthorized access.

- In high-security environments (e.g., pharmaceuticals or luxury goods), cryptographic authentication ensures that only authorized readers can access the tag’s data.

- Tamper-Proofing: Certain RFID tags are designed to detect tampering. If someone tries to remove or interfere with the tag, it will either deactivate or show signs of tampering.

- Compliance: Depending on your industry (e.g., healthcare, finance), you may need to comply with data security regulations such as GDPR or HIPAA when handling customer or asset information stored in RFID tags. Ensuring that RFID systems meet these regulatory requirements is essential to protect sensitive data and maintain compliance.

As sustainability becomes a global priority, the circular economy is widely embraced as a solution. RFID tags, with their advanced tracking capabilities, play a crucial role as data carriers in fostering a greener world. Throughout the product lifecycle, RFID enhances sustainability at each stage:

Product Design

Integrates lifecycle thinking and modular design into products to ensure recyclability and sustainable lifecycle management.

Sourcing

Enables precise tracking for responsible sourcing and waste reduction.

Manufacturing

Monitors production to minimize waste and optimize resource use.

Distribution

Improves supply chain transparency and efficiency, reducing the carbon footprint through optimized logistics.

Use & Repair

Provides real-time data on product usage, maintenance and repair, extending product life and reducing the need for replacements.

End of Life

Supports recycling or even upcycling programs by enabling accurate sorting and tracking of recyclable materials, promoting efficient resource recovery.