For IOT

Case Background

Business Challenges

THE ACTIVITY HAS ADDRESSED A HIGH PRIORITY FOR THE SEAFOOD INDUSTRY.

The time for change is now

THE ACTIVITY WAS CHALLENGING, REQUIRED A HIGH LEVEL OF INNOVATION, AND DIRECT ACTION AND/OR EXTENSION TO ACHIEVE THE PLANNED OUTCOME

Following a road not yet made

Strategic Objectives

THE ACTIVITY WAS END-USER DRIVEN AND PRODUCED OUTCOMES THAT CONTRIBUTED TOWARDS PROTECTING OR REHABILITATING AQUATIC ENVIRONMENTS, OR REDUCING ADVERSE SEAFOOD INDUSTRY IMPACTS ON THE ENVIRONMENT.

Local fisher driven solution to a global problem

Tom was a plumber before turning to fishing and knew of several insulation materials that he believed could be repurposed to provide an alternative packaging solution. That was the challenge and where the research and development was focussed through a new company, TomKat Global Solutions. Ensuring that the boxes could be re-used, and the materials could be recycled was essential to meet the ‘cradle to cradle’ principles of sustainability. They wanted a durable product, that could be cleaned and re-used many times without the need for single-use plastic liners to protect against leakage, and that could be packed flat for easy storage and transportation. This led them to focus on fundamental reuse and recycling processes for the KoolPak system. They have ensured no material is co-mingled: a significant issue with many alternative products as it limits any post-use recycling. The material spec for the KoolPak has been developed to be fully recyclable, delivering thermal performance in a form that exceeds market needs and expectations.

Re-use has many advantages for the user and the environment. Economically, users benefit as with each re-use they are working toward cost negative packaging, and the environment benefits as ultimately less boxes need to be made. Simply, if each KoolPak is used five times, only 2 million KoolPaks need to be made to meet the current Australian use of 10 million polystyrene boxes each year.

Product solution

What is the TomKat KoolPak?

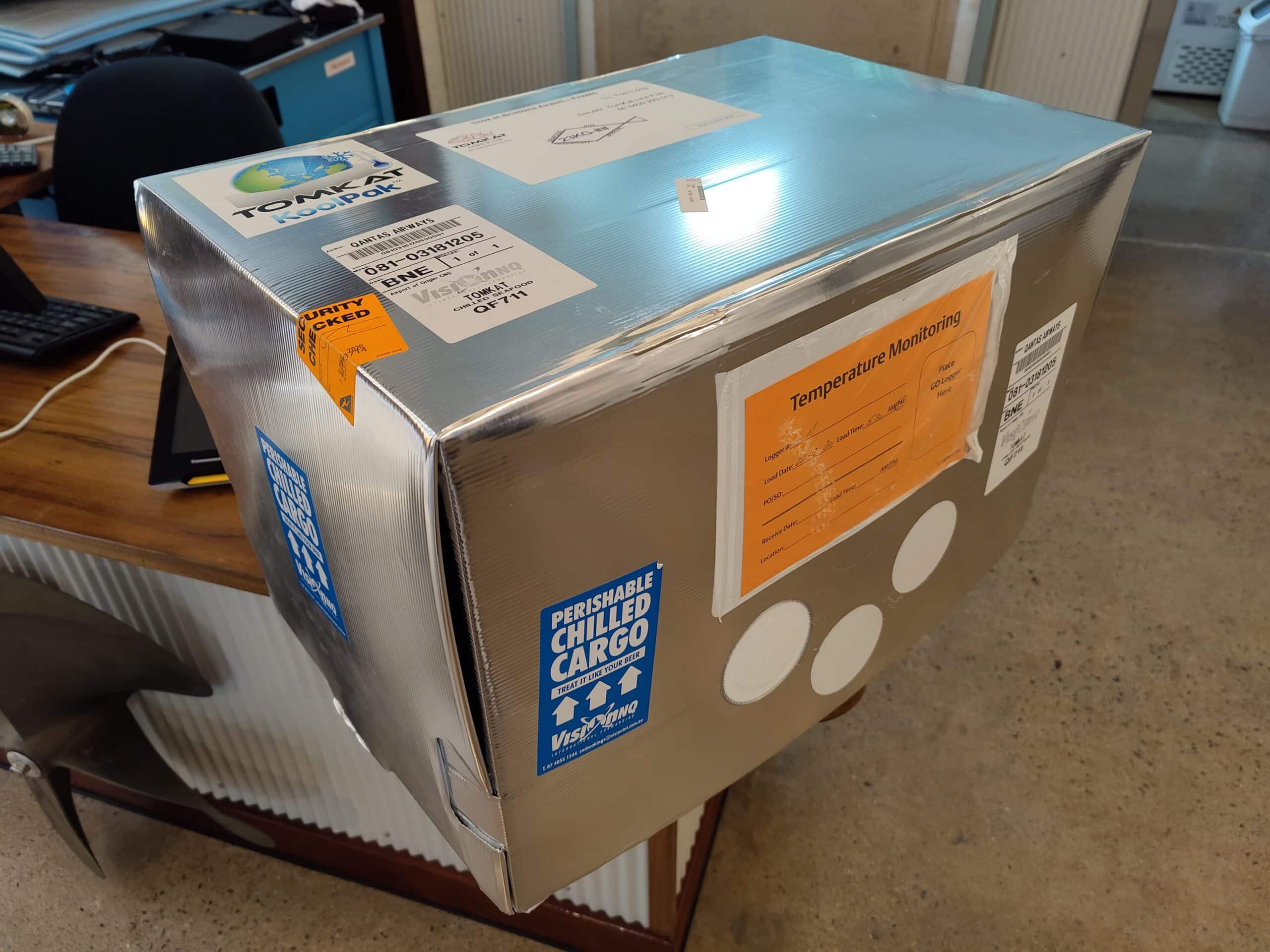

The TomKat KoolPak® is the creation of innovators and fishers Tom and Kath Long. Their family-owned business TomKat Line Fish is a sustainable line fishing company that operates on the outer Barrier Reef in Far North Queensland. TomKat KoolPak®, a tough, lightweight, container with all the thermal qualities needed for transporting and storing fresh foods and other cold chain products such as medicines. The technology behind the product development is not just reusable and recyclable; the inclusion of NFC tags in all 3 components – the box, lid and thermal liner – allows each to be scanned off post multiple uses at an authorised recycling centre, so clients can validate their environmental credentials

It is an environmentally responsible, robust, and stackable lightweight thermally insulated box. With excellent proven, reliable thermal performance, and designed for multiple use, the KoolPak system protects product, preserves the environment, and improves social license. The patented, sealed antimicrobial food-grade liner provides additional protection from contamination. Flat packable for efficient transportation and storage and 100% recyclable, the KoolPak embraces the cradle-to-cradle principles of sustainability.

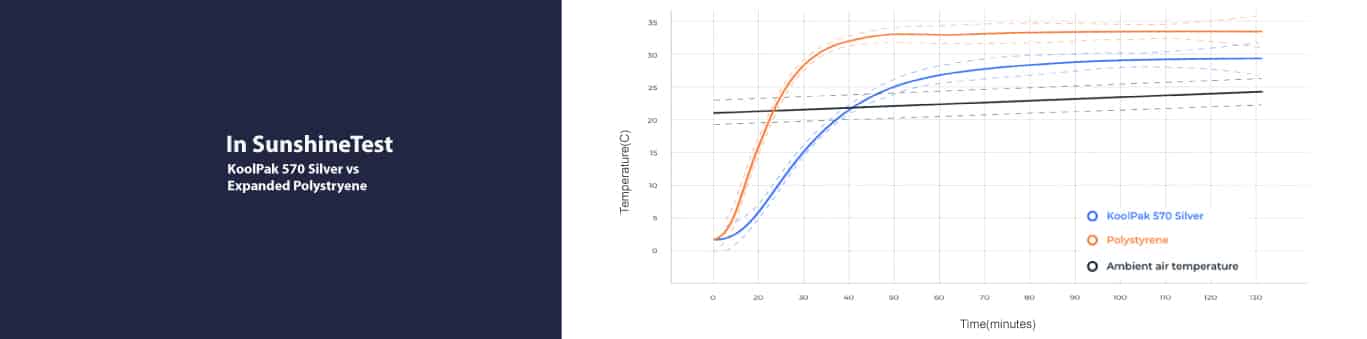

Independent research by the Queensland Department of Agriculture and Fisheries released official test data illustrating the effective thermal performance of the KoolPak. The results below show the KoolPak has better thermal performance.

Business Benefits

Packaging plus + now with built in next generation tracking technology

In parallel with SAG and improvements to temp sensor tag capability, LUK has made significant advancement with our software that has allowed gate scanning equipment developed with Feig Electronic to read multiple tags at once, at speed, including temperature sensor tags. To maximise users scanning the boxes, each is embedded with a battery free temperature sensing tag so users can monitor the temperature of their consignment without the need to open the box.

The block chain tracking and traceability function has proved popular in market tests. For producers, for instance, it has the potential to provide data from the fisher or farmer along the entire supply chain to a restaurant where the data can be translated into a QR code and added to a menu. For Tom and Kath, personally, it also means that any part of a KoolPak washed-up on a beach can be tracked backwards to work out how it got there. It is all part of the Longs’ ethos of "social responsibility in action" which underpins the business.

THE ACTIVITY INVOLVED OTHER USERS OF THE ENVIRONMENT

The production and transport of food is a major global industry, and it is projected to grow strongly in Australia over the next 20 years as export capacities expand. In 2018, more than 23 million tonnes of foodstuffs worth $42 billion based on farm gate values passed through the Australian cold food chain. The TomKat KoolPak® is designed to assist producers deliver their products fresh and safe, and with the KoolPak App, they can also prove the provenance of their produce.

Spill over environmental benefits can also be attributed to the KoolPak for other sectors. Transport logistics have considerable environmental impact in the use of fuel, and emission of greenhouse gases. Existing polystyrene packaging is inefficient to transport to customers before they even use it. KoolPaks can be delivered by the pallet, flat packed for efficient transportation. Each pallet holds up to 140 KoolPaks which is approximately three times as many boxes as an equivalent sized polystyrene box or other option which is not flat packable.

Our Track & Trace Supply Partners - Environmentally Focused

“We are all users and have a role to play in protecting and improving the environment. We live in a pristine part of the world. We want to keep it that way for generations to come.”

SAG: Originally introduced to us by Texas Instruments, SAG has been instrumental in providing solutions for our NFC requirements, with specific focus on the battery-less NFC temp sensor tag. Our tag requirements are challenging, particularly when you consider the primary reading device is a mobile phone, multiple layers of material to read through and no battery. Other alternatives to NFC such as QR Codes, bar code etc were evaluated, however only NFC provides an effective way of registering the 3 KoolPak components as an assembled unit to a data base or blockchain in battery-less form.

NFC is central to our track & trace, SAG is ‘best in business’ not only from a technical & development perspective but also with tag manufacture and ability to supply in volume.

LUK Solutions: As with SAG, LUK have been on-board the project from the very start (2019) and instrumental in development of the KoolPak App, integration of NFC and gate scanner technologies within that. In combination they have systematically worked through the significant challenges involved, finding workable solutions to complex problems.

A standout for us, both SAG & LUK saw the value of the project even though it was a ‘start-up’. They took on the risk of committing resources & time, we are very grateful to have them by our side and sharing the vision of KoolPak.