for Industrial

Case Background

Business Challenges

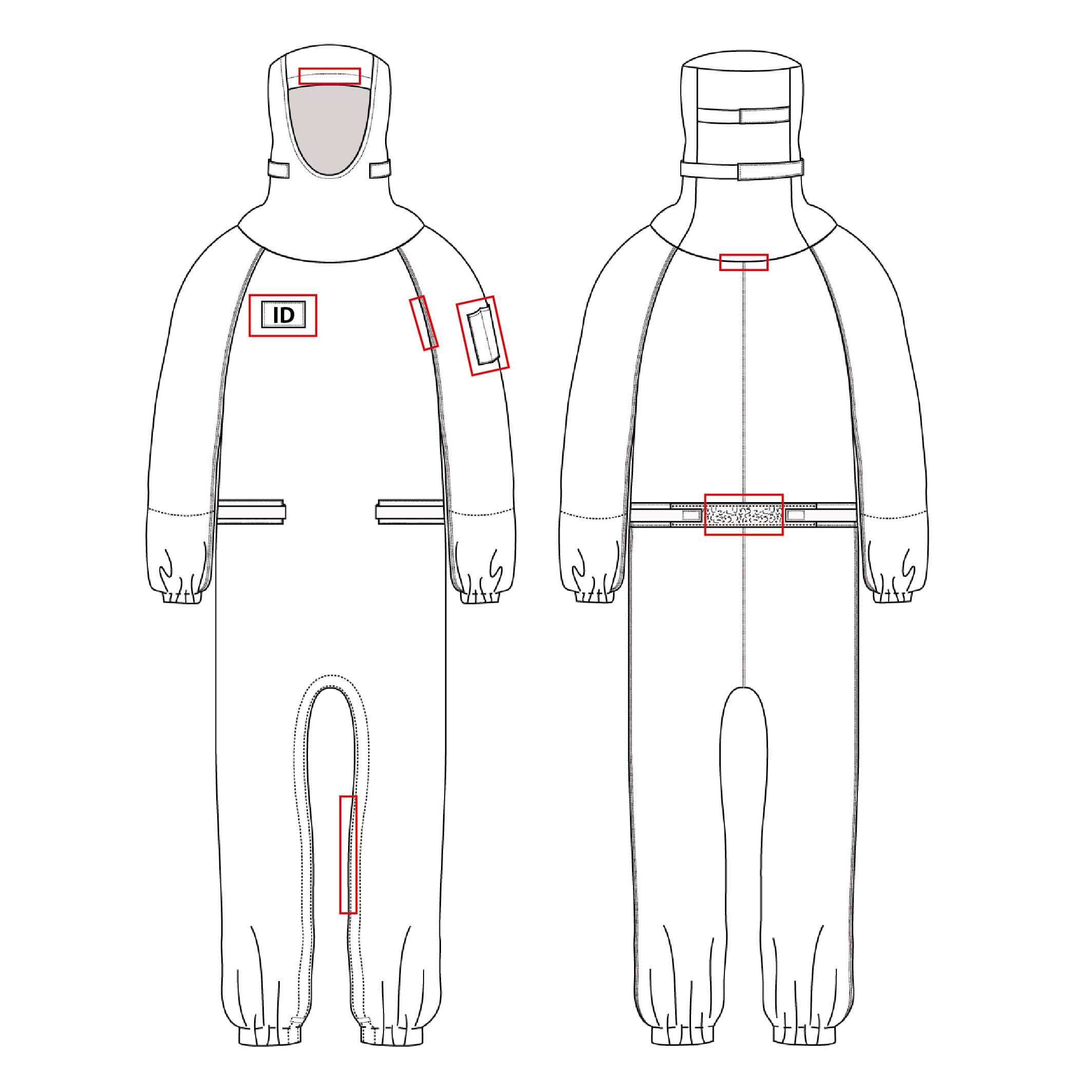

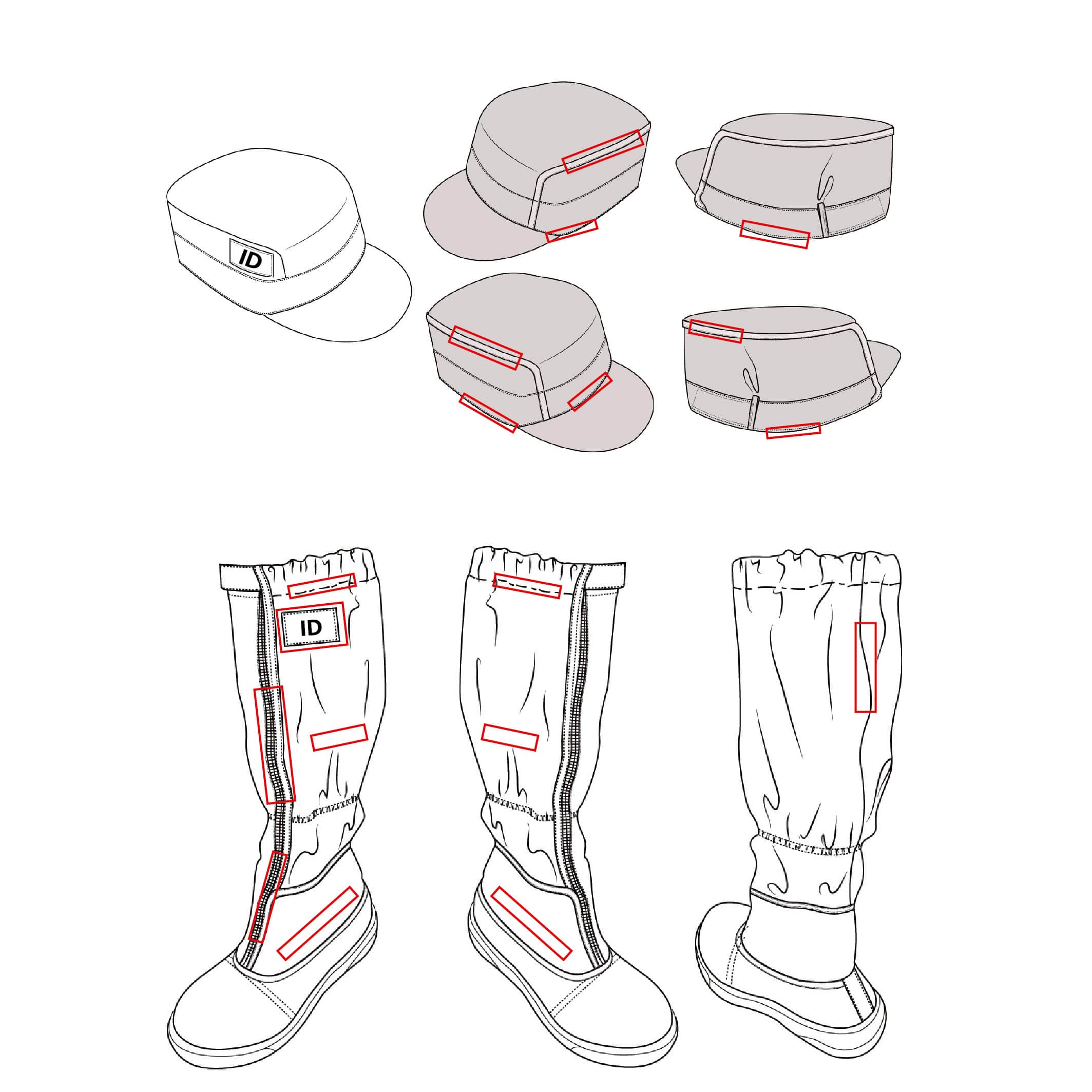

Ruth’s service offering includes cleanroom garments laundry, inventory management and the lifecycle control of each individual garment (such as face masks, hair covers, coveralls, shoe covers, and hoods) from daily maintenance to final discard. The inbound and outbound logistics was validated merely through barcode scanning and managed at bin-level without any item-level visibility which inevitably lead to item losses and hidden cost. In particular, the sorting, repairing, matching processes are done entirely manually which make the processes error-prone and time-consuming. The financial losses attributed to garment loss, misplace, mismatch, and undercharge during the manual processes is festering every single day. As a result, the discussion of RFID laundry tag and system installation has been raised for quite some time; however, the conventional RFID laundry tags pose some challenges in consideration of the material to survive under the harsh industrial laundry criteria and the discomfort stemmed from the stiffness and inflexibility of a chunky tag housing might potentially cause interruption during the operation. Nevertheless, the overall operation inefficiency and labor-intensive tasks involved has urged Ruth to make a leap to innovative RFID technologies which help to realize process automation and tackle the challenges addresses the following highlights:

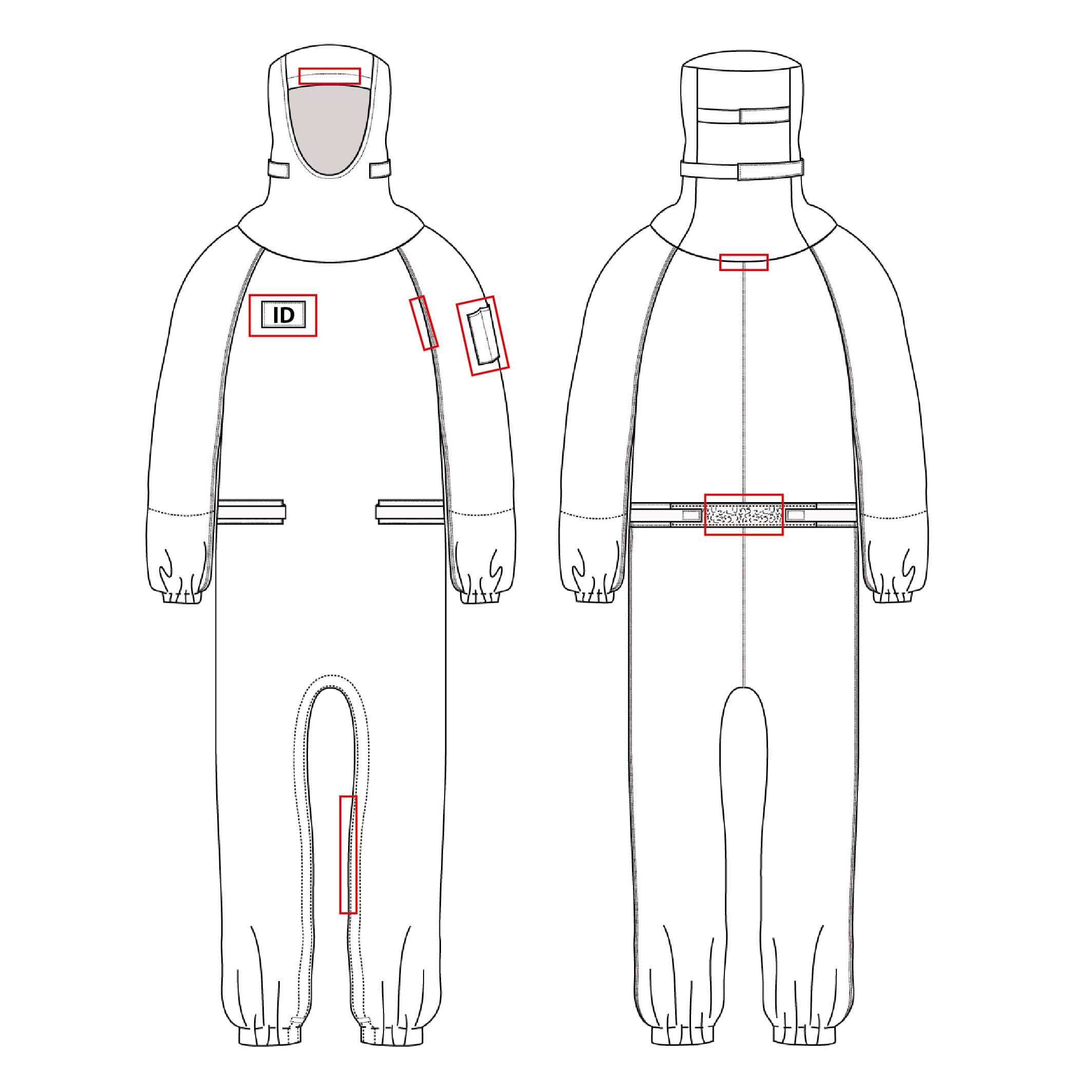

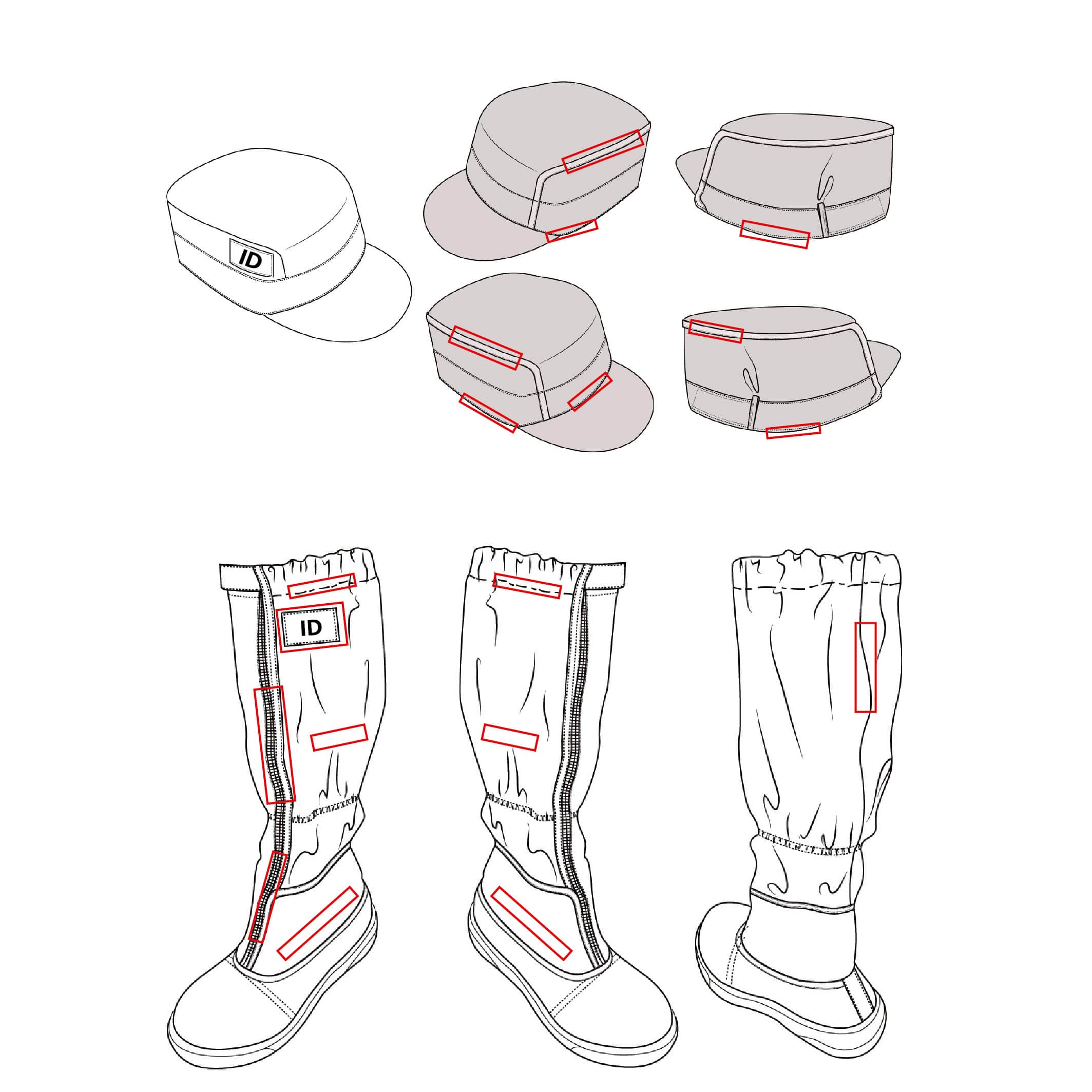

This RFID tag needs to be designed as a type of yarn which is embeddable yet flexible to be sewn in cleanroom garments to offer sufficient comfortability and ensure that operations can continue uninterruptedly.

The life expectancy of a cleanroom garment is about 50 industrial wash cycles before losing the filter ability against ESD and protection that the garment provides. That’s is to say, in addition to an embeddable and flexible construction, the advantages such as laundry resistance, high temperature resistance, chemical resistance, and roller pressure resistance also need to be taken into consideration.

Strategic Objectives

- Develops the worlds’ first mass production line for the cutting-edge yarn type RFID tag to ensure its manufacturability and producibility.

- Enables the world’s first automatic identification system tailored for industrial laundry of cleanroom garments to accelerate the digital transformation and mitigate labor-intensive works.

Product Solution

- AATCC135 ≥100 cycles & CNS 8150 Sewn seam strength ≥ 40N

- ASTM D2256 at a 5m gauge length and at an extension strength ≥ 1kgf

- ISO 7854 at a 5 m gauge length at an flex cracking resistance ≥ 1000 cycles

SAG has partnered with NXP for years when there is a need for specialty RFID tags to overcome challenges in every potential application and RFID Yarn® is a breakthrough of miniaturization RFID tag. On the technical side, we use NXP UCODE 8 RFID chip with its advantages in chip sensitivity value to enable long read range performance and fast read rate among highly dense tag population. Such features help to facilitate great efficiency in an item-level management use case. Meanwhile, this yarn-type RFID tag features its embeddable and flexible design to be laundry-resistant, high-temperature resistant, chemical-resistant, roller-pressure resistant to push the envelope to impossible tagging in laundry become possible.

Figure 1

Figure 2

Figure 1.0

Figure 1.0

Business Benefits

Each partner played a significant role that allowed the overall project to focus on application-specific pain points and flow seamlessly. Ruth now has a standards-based, service-oriented architecture for the business process improvement it needed to achieve scalability, sustainability and profitability. The RFID solution provides the standardized infrastructure in cleanroom garments laundry and enables the business benefits as following (Take a truck about 7 tons of cleanroom garments as an example):

- Achieved 48% reduction in processing time

- Achieved 45% increase in productivity.

- Achieved 30% the number of workers reduction