Choose Year

Choose Year

Choose Year

New RFID Plus One Projects Realized!

RFID expert SAG has been manufacturing a wide range of RFID products for 20 years: This includes labels and inlays, tags, keyfobs, sensor tags, cards and customized solutions. The focus is especially on RFID applications in industry, healthcare and the automotive sector. In the future, production capacity will be increased even further: the construction of the new main site is scheduled for completion as early as December 2022. At the same time, SAG is focusing on a new marketing strategy, including a new website. Jasmine Shih, Marketing Director at SAG, explains the background to the new strategy in an interview.

Of particular note is the SAG Temp Tracker, an NFC-enabled label with app support that measures temperature. Originally developed as a solution for refrigerated containers for perishable goods, the solution can also be used for the transport of temperature-sensitive substances such as vaccines. A smartphone can be used to read the temperature history. An alert is sent in the event of temperature deviations.

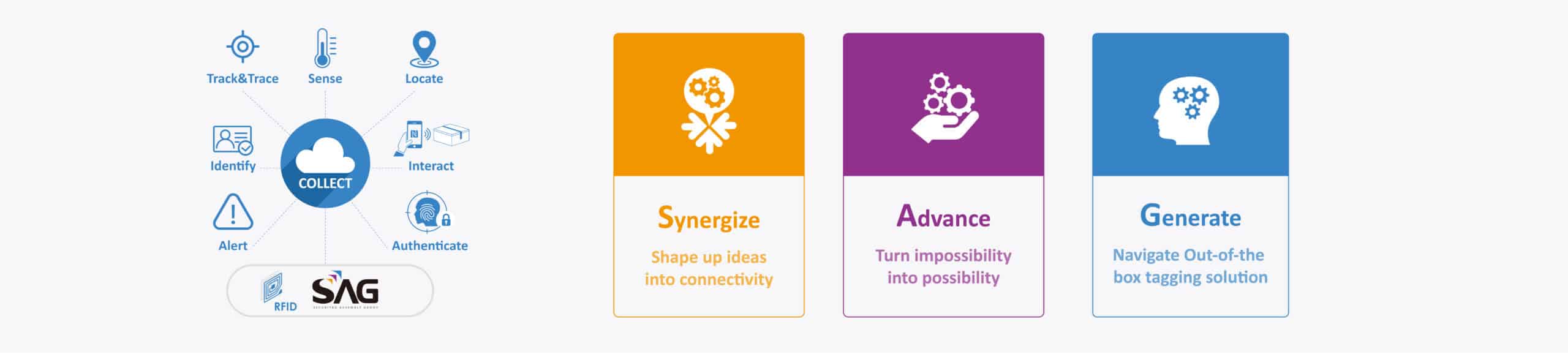

New Solutions for Future Connectivity

What does ‘future connectivity’ mean for SAG, and what solutions are being developed for it?

Jasmine Shih: Future connectivity means expanding the IoT by connecting an increasing number of objects with RFID. To do this, SAG leverages its expertise in materials science, RFID design and mechanical innovation. With these core competencies, SAG is developing new tags for applications where unique challenges still prevent RFID deployment.

How are the products adapted to these challenges?

Shih: SAG works with partners in system integration to optimize performance between the tag, the antenna and the reader module, for example. In addition, for example, functionality on metal, temperature or chemical resistance are required. In other application areas, the tag is to be applied to particularly small surfaces or integrated directly into products.

For which applications have the latest solutions been implemented?

Shih: The first RFID line for cleanroom laundry is currently being developed with Ruth Technology. The RFID Yarn® used is integrated directly into the clothing and is resistant to industrial laundry of up to 100 times wash cycles as well as to high-temperature and chemicals. In another project, an automated warehouse management system is being developed for the intralogistics of China Steel Corporation (CSC).

What role does RFID Plus One play in this regard?

Shih: RFID Plus One is the combination of RFID with additional functions via sensors. These include temperature, pressure or humidity sensors, for example. The tags have extended functionalities, but are still passive or semi-passive. With this innovation, even more objects will be connected to the IoT.

Of particular note is the SAG Temp Tracker, an NFC-enabled label with app support that measures temperature. Originally developed as a solution for refrigerated containers for perishable goods, the solution can also be used for the transport of temperature-sensitive substances such as vaccines. A smartphone can be used to read the temperature history. An alert is sent in the event of temperature deviations.

What are SAG's goals for future connectivity?

Shih: SAG's vision is to master the most challenging tagging applications and develop solutions for them. This means adding even more functionalities to RFID tags. SAG sees itself as an enabler to help customers with RFID realize the potential of the technology and design new, innovative solutions.